TFT LCD (Thin Film Transistor) is a thin film transistor, it is that each liquid crystal pixel is driven by a thin film transistor integrated behind the pixel, so that it can achieve high speed, high brightness, and high contrast. It is one of the best LCD color display devices, its display effect is close to that of CRT monitors. It is now the mainstream display device on laptops and desktops.

Each pixel of the TFT display is controlled by the TFT integrated on itself and it is an active pixel. Therefore, not only it can the speed be greatly improved, but the contrast and brightness can also be greatly improved, while the resolution has also reached a very high level.

TFT-LCD liquid crystal display is a thin film transistor type liquid crystal display, also known as "true color" (TFT). TFT liquid crystal is equipped with a semiconductor switch for each pixel. each pixel can be directly controlled through point pulses. Therefore, each node is relatively independent and can be controlled continuously. This not only improves the response speed of the display screen, but also allows precise control to display color gradation, so the colors of TFT LCD screen are more realistic.

TFT Display is a thin film transistor active matrix liquid crystal display device. TFT liquid crystal displays design a field-effect switch tube on each pixel, making it easy to realize a true-color, high-resolution liquid crystal display device. Today's TFT-type liquid crystals generally achieve more than 18-bit color (218 colors), or even 24-bit color. In terms of resolution, VGA (640×480), SVGA (800×600), XGA (1024×768), SXGA (1280×1024), and even UXGA (1600×1200) have become a reality.

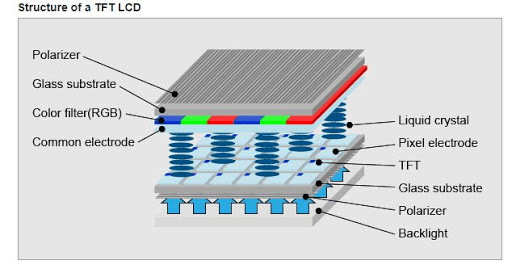

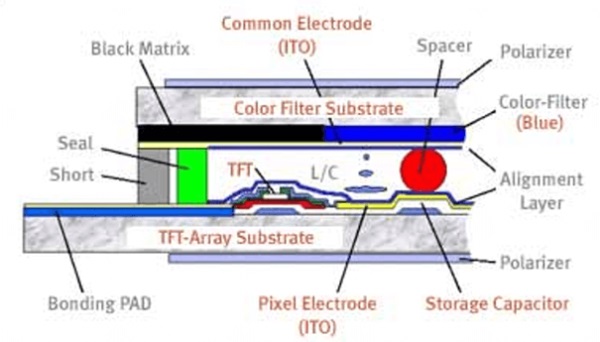

When the screen is powered on, the backlight emits white light, which is emitted by the light guide plate to illuminate the entire screen. The diffusion film softens the light, the prism module ensures that the light can go in the correct direction, and the polarizer filters out light from other directions. Only vertically polarized light is allowed to pass through. TFT controls the voltage of sub-pixels as needed, affects the degree of distortion of liquid crystal molecules, and controls the brightness of light. When light passes through the liquid crystal and the color filter film, there is red light, green light, and blue light. the last layer of polarizer only allows horizontally polarized light to pass through, and the LCD displays the picture.

(1) Large area: The first generation of large-area glass substrate (300mm × 400mm) TFT-LCD production line was put into production in the early 1990s. By the first half of 2000, the area of the glass substrate had expanded to 680mm × 880mm, and the glass was nearly 950mm × 1200mm. Baseboard will also be put into operation.

(2) High integration: The resolution of the 1.3-inch TFT chip used for liquid crystal projection is XGA and contains one million pixels. The 16.1-inch TFT array with a resolution of SXGA (1280×1024) has a film thickness of only 50nm of amorphous silicon, and TABONGLASS and SYSTEMONGLASS technologies. Its IC integration level, requirements for equipment and supply technology, and technical difficulty all exceed traditional LSI.

(3) Powerful function: TFT, as a matrix address selection circuit, improves the light valve characteristics of liquid crystal. For high-resolution displays, precise control of the object elements is achieved through voltage regulation in the 0-6V range (its typical value is 0.2 to 4V), making it possible for the LCD display to achieve high-quality, high-resolution displays.

(4) Low cost: Glass substrates and plastic substrates fundamentally solve the cost problem of large-scale semiconductor integrated circuits and open up a broad application space for the application of large-scale semiconductor integrated circuits.

(5) Process flexibility: In addition to traditional film formation processes such as sputtering, CVD (Chemical Vapor Deposition), MCVD (Molecular Chemical Vapor Deposition), laser annealing technology has also begun to be applied, which can produce amorphous films, polycrystalline films, and Single crystal films can be produced. Not only silicon films can be produced, but other II-VI and III-V semiconductor films can also be produced.

(6) Wide range of applications. LCD flat panel displays based on TFT technology are a pillar industry in the information society. The technology can be applied to thin film transistors which are growing rapidly.

Hicenda focus on the R&D and manufacturing of industrial displays, industrial-grade touch screens and optical bonding products. Its products are widely used in medical equipment, industrial handheld terminals, Internet of Things terminals and smart homes.

Contact: David

Phone: +8618665976986

Tel: +8675521563288

Email: [email protected]

Add: 305 Room A Buiding Huafeng International Robot Industrial Park Xixiang Bao'an